- 您现在的位置:买卖IC网 > Sheet目录968 > CB5440-000 (TE Connectivity)HEAT SHRINK TUBING

�� �

�

�

�Page� 4�

�SPECIFICATION� RW-2016� ISSUE� 8�

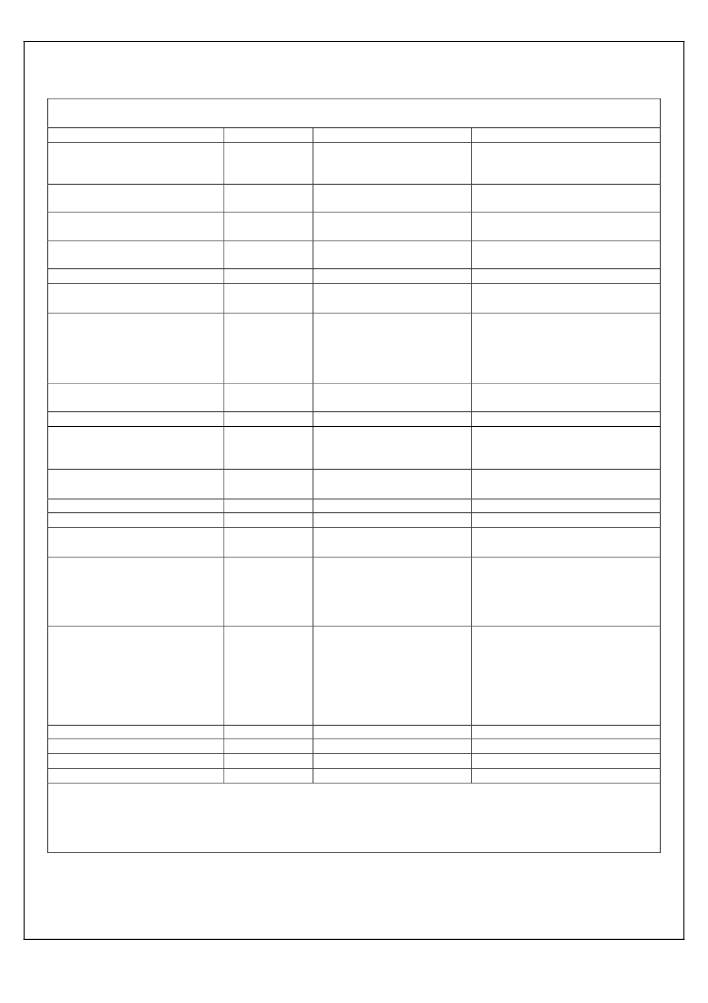

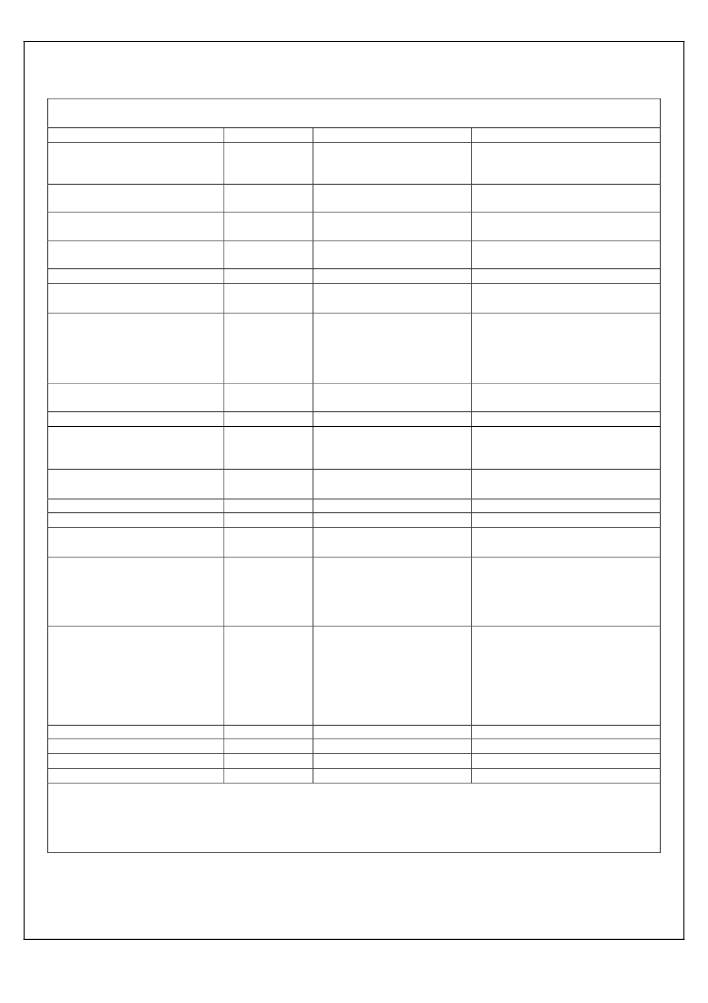

�TABLE� 2�

�REQUIREMENTS�

�PROPERTY�

�UNIT�

�XFFR�

�TEST� METHOD�

�PHYSICAL�

�Dimensions�

�mm� (inch)�

�In� accordance� with� Table� 1�

�Section� 6.1�

�ASTM� D� 2671�

�Longitudinal� Change�

�percent�

�+1,� -10�

�Section� 6.1�

�ASTM� D� 2671�

�Tensile� Strength�

�MPa� (psi)�

�9.0� (1,300)� minimum�

�Section� 6.2�

�ASTM� D� 638�

�Ultimate� Elongation�

�percent�

�150� minimum�

�Section� 6.2�

�ASTM� D� 638�

�Specific� Gravity�

�Low� Temperature� Flexibility�

�4� hrs� at� -55� ±� 2� °� C�

�Heat� Resistance�

�168� hrs� at� 175� ±� 2� °� C�

�Followed� by� tests� for:�

�1.5� maximum�

�No� cracking�

�ASTM� D� 792�

�SAE-AMS-DTL-23053�

�Tensile� Strength�

�Ultimate� Elongation�

�MPa� (psi)�

�percent�

�8.4� (1,200)� minimum�

�100� minimum�

�ASTM� D� 638�

�ASTM� D� 638�

�ELECTRICAL�

�Dielectric� Strength�

�Volume� Resistivity�

�kV/mm� (V/mil)�

�ohm-cm�

�10� (250)� minimum�

�10� 12� minimum�

�ASTM� D� 2671� *Note� 1�

�ASTM� D� 876�

�CHEMICAL�

�Copper� Mirror� Corrosion�

�16� hours� at� 120� ±� 2� °� C�

�Copper� Contact� Corrosion�

�16� hrs� at� 120� ±� 2� °� C�

�No� removal� of� copper�

�No� pitting� or� blackening� of�

�copper�

�SAE-AMS-DTL-23053�

�SAE-AMS-DTL-23053�

�Halogen� Content�

�Flammability�

�Water� Absorption�

�percent� (ppm)�

�seconds�

�percent�

�0.1� (1,000)� maximum�

�15� maximum�

�0.2� maximum�

�Section� 6.3�

�ASTM� D� 2671� Procedure� A�

�ASTM� D� 570�

�24� hrs� at� 23� ±� 2� °� C�

�Fungus� Resistance�

�Followed� by� tests� for:�

�ISO� 846� Method� B�

�Tensile� Strength�

�Ultimate� Elongation�

�Dielectric� Strength�

�Fluid� Resistance�

�MPa� (psi)�

�percent�

�kV/mm� (V/mil)�

�9.0� (1,300)� minimum�

�150� minimum�

�7.9� (200)� minimum�

�ASTM� D� 638�

�ASTM� D� 638�

�ASTM� D� 2671�

�SAE-AMS-DTL-23053�

�24� hours� at� 23� ±� 2� °� C�

�JP-8� Fuel� (MIL-DTL-83133)�

�Hydraulic� Fluid� (MIL-H-5606)�

�Followed� by� tests� for:�

�Tensile� Strength�

�Ultimate� Elongation�

�Acid� Gas� Generation�

�Smoke� Index�

�Toxicity� Index�

�Oxygen� Index�

�MPa� (psi)�

�percent�

�percent�

�5.0� (720)� minimum�

�100� minimum�

�2� maximum�

�25� maximum�

�5� maximum�

�30� minimum�

�ASTM� D� 638�

�ASTM� D� 638�

�MIL-C-24643�

�NES� 711� with� Wire� Support� Screen�

�NES� 713�

�ASTM� D� 2863�

�*Note� 1:� Recover� specimens� on� the� metal� mandrels� for� 10� minutes� minimum� at� 200� ±� 3� °� C� or� until� the� tubing� is�

�completely� recovered� on� the� mandrels.�

�If� this� document� is� printed� it� becomes� uncontrolled.� Check� the� latest� revision.�

�?� 2007-2008� Tyco� Electronics� Corporation.� All� rights� reserved�

�发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

CBA-NF-NM1

CABLE ASSY N MALE-N FEM 1000MM

CBA-NM-NM1

CABLE ASSY N MALE-N MALE 1000MM

CBA-SMA-FME1

CABLE ASSY SMA F-FME F 100MM

CBA-SMA-MMCXRA

CABLE ASSY SMA F-MMCX M RA 100MM

CBA-SMA-SMA18

CBL ASSY SMA M-SMA M REV 1800MM

CBA-SMA-SMB1

CABLE ASSY SMA F-SMB F 100MM

CBA-SMAM-NM1

CBL ASSY N MALE-SMA M REV 1000MM

CC-5190

CABLE CARRIER ASSEMBLY

相关代理商/技术参数

CB5442-000

功能描述:热收缩管和套管 XFFR-20X25 RoHS:否 制造商:3M Electronic Specialty 类型:Tubing 材料:Polyolefin, Flexible 颜色:Clear 最低收缩温度:+ 100 C 恢复直径: 长度:100 ft 内径:1.5 in 收缩率:2:1

CB5443-000

功能描述:热收缩管和套管 XFFR-20X4 RoHS:否 制造商:3M Electronic Specialty 类型:Tubing 材料:Polyolefin, Flexible 颜色:Clear 最低收缩温度:+ 100 C 恢复直径: 长度:100 ft 内径:1.5 in 收缩率:2:1

CB5444-000

功能描述:热收缩管和套管 XFFR-30X25 RoHS:否 制造商:3M Electronic Specialty 类型:Tubing 材料:Polyolefin, Flexible 颜色:Clear 最低收缩温度:+ 100 C 恢复直径: 长度:100 ft 内径:1.5 in 收缩率:2:1

CB5445-000

功能描述:热收缩管和套管 XFFR-30X4 RoHS:否 制造商:3M Electronic Specialty 类型:Tubing 材料:Polyolefin, Flexible 颜色:Clear 最低收缩温度:+ 100 C 恢复直径: 长度:100 ft 内径:1.5 in 收缩率:2:1

CB5446-000

功能描述:热收缩管和套管 XFFR-40X4 RoHS:否 制造商:3M Electronic Specialty 类型:Tubing 材料:Polyolefin, Flexible 颜色:Clear 最低收缩温度:+ 100 C 恢复直径: 长度:100 ft 内径:1.5 in 收缩率:2:1

CB5447-000

功能描述:热收缩管和套管 XFFR-48-15/97 CB5364-000 RoHS:否 制造商:3M Electronic Specialty 类型:Tubing 材料:Polyolefin, Flexible 颜色:Clear 最低收缩温度:+ 100 C 恢复直径: 长度:100 ft 内径:1.5 in 收缩率:2:1

CB5448-000

功能描述:热收缩管和套管 XFFR-48-20/97 RoHS:否 制造商:3M Electronic Specialty 类型:Tubing 材料:Polyolefin, Flexible 颜色:Clear 最低收缩温度:+ 100 C 恢复直径: 长度:100 ft 内径:1.5 in 收缩率:2:1

CB5449-000

功能描述:热收缩管和套管 XFFR-48-40/97 RoHS:否 制造商:3M Electronic Specialty 类型:Tubing 材料:Polyolefin, Flexible 颜色:Clear 最低收缩温度:+ 100 C 恢复直径: 长度:100 ft 内径:1.5 in 收缩率:2:1